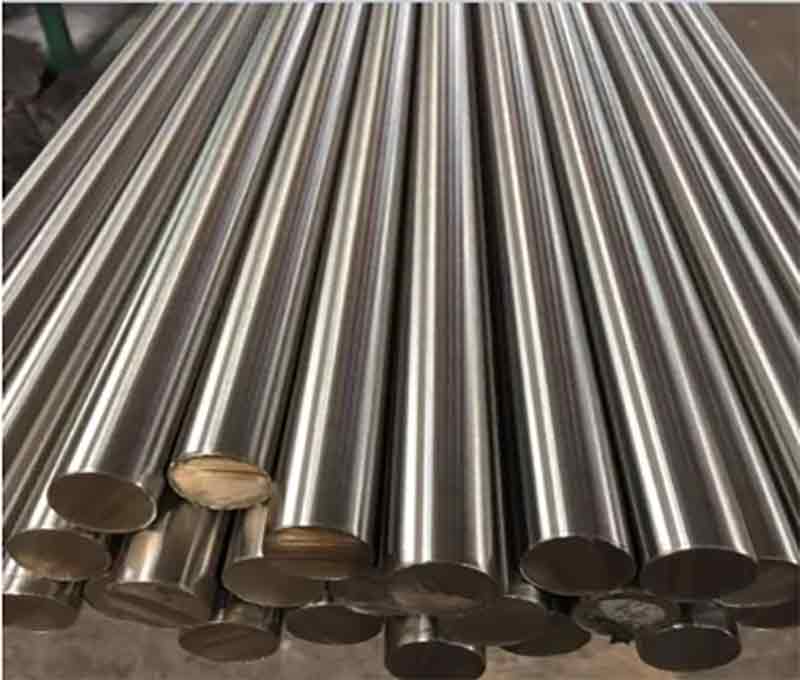

4130 Steel Round Bar

4130 Steel Round Bar/SAE4130 AISI4130 Steel Rod

4130 steel Round Bar Machining and heat treatment

Machining

4130 steel has a machinability rating of about 70% (when annealed and cold drawn, relative to AISI 1212 steel with a machinability of 100%). It can be machined using standard machining processes such as turning, milling, drilling, and grinding. However, proper tool selection and cutting parameters are essential to achieve good surface finish and tool life. For example, using carbide tipped tools and appropriate cutting speeds and feeds can optimize the machining process.

Heat Treatment

- Quenching: The recommended quenching temperature is 880°C, followed by rapid cooling in water or oil. This process hardens the steel by transforming the microstructure to martensite.

- Tempering: After quenching, tempering is carried out at 540°C, with subsequent cooling in water or oil. Tempering relieves the internal stresses induced during quenching and improves the toughness of the steel while maintaining an appropriate level of hardness.

- Normalizing: Involves heating the steel to 870°C and then air – cooling. Normalizing refines the grain structure, improves the mechanical properties, and provides a more uniform microstructure.

4130 steel round bar chemical composition&mechanical Properties

Chemical Composition

Element | Content (%) |

Carbon (C) | 0.28 – 0.33 |

Silicon (Si) | 0.15 – 0.35 |

Manganese (Mn) | 0.40 – 0.60 |

Sulfur (S) | ≤ 0.040 |

Phosphorus (P) | ≤ 0.035 |

Chromium (Cr) | 0.80 – 1.10 |

Nickel (Ni) | ≤ 0.030 |

Copper (Cu) | ≤ 0.030 |

Molybdenum (Mo) | 0.15 – 0.25 |

Mechanical Properties

Property | Metric Value | Imperial Value |

Tensile Strength, Ultimate | ≥930 MPa (in quenched and tempered state) | ≥135000 psi |

Tensile Strength, Yield | ≥785 MPa (in quenched and tempered state) | ≥114000 psi |

Elongation at Break | ≥12% | ≥12% |

Reduction of Area | ≥50% | ≥50% |

Impact Energy (Akv) | ≥63 J | ≥46.5 ft – lb |

Hardness (Brinell) | ≤229 HB (in as – delivered state, before heat treatment) | ≤229 HB |

4130 steel round bar Applications

- Aerospace Industry: 4130 steel round bar is used in the manufacture of aircraft components such as landing gear parts, engine mounts, and structural members. Its high strength to weight ratio and excellent fatigue resistance are crucial for ensuring the safety and reliability of aircraft in flight.

- Automotive Industry: It is employed in the production of automotive components like crankshafts, axles, and gears. These parts need to withstand high stresses and cyclic loading during the operation of the vehicle, and the properties of 4130 steel make it well-suited for such applications.

- Oil and Gas Industry: In equipment such as drill collars and valves, 4130 steel round bar is used due to its ability to resist corrosion and high – pressure environments. The chromium and molybdenum in the steel contribute to its enhanced corrosion resistance.

- General Machinery: For manufacturing shafts, spindles, and high load bearing components in various machinery, 4130 steel round bar provides the necessary strength and durability.